Ground breaking policies: labour intensive road construction A case study 50 years into the ILO century / Jens Müller

Category : Centenary - Testimonials

At the outset of the World Employment Programme (WEP) in 1969/70, specific policy initiatives on using labour intensive techniques in infrastructure projects were still in an embryonic stage. The extensive WEP research programme, the country missions and the World Employment Conference still lay ahead. At this time, in 1970, the author shared his experience of how labour intensive techniques came to the rescue of a road construction project that had initially been planned to rely on highly capital intensive material and techniques.* The present text summarizes an article describing the case study in the International Labour Review.

Fifty years later, as the ILO marks its centennial, these lessons remain relevant to the ILO’s policies on employment intensive investments.

The initial project

The Public Works Department of a subtropical African country was tasked to transform a 480 kilometre dirt road into all-weather gravel road. The road was to be complemented with other public works (drainage works, 20 bridge constructions and realignments to eliminate dangerous bends) but the case study focused solely on the provision of a compact gravel road.

A young, inexperienced civil engineer, the author, was put in charge of the project through bilateral funding. Thirteen national technical and inspection staff were planned to assist, but only 6 and a half were actually assigned.

The equipment planned was highly mechanized and sophisticated and had to be imported. It consisted of four construction units composed of over 20 different vehicles/earth moving machines, some of which had hydraulic systems. It took nine months for most of the equipment to arrive. Some was lost en route due to rough terrain over the 1,000 kilometres from the nearest harbor.

In addition to the above shortcomings, other constraints soon surfaced. Operators and drivers had to be trained, especially for the hydraulic equipment but there were no trainers. Maintenance and repair were constant issues with long delays for spare parts and qualified personnel. The supply of fuel and lubricants, especially for the hydraulic systems, was uncertain and also frequently delayed. All of this resulted in under-utilization of equipment and long periods of idle time.

Had the project operated according to plans, under ideal circumstances, the direct operational cost of 1 kilometre of road using capital-intensive methods, was calculated at US$ 500. And with a reasonable rate of utilization of the machinery, 1 kilometre could be graveled in approximately 3 days. However, taking into account the idle time of the machines, the theoretical time was reduced from 3 days to 2.3 days.

The actual implementation of the project

With equipment missing or under repair soon after the start of the operations, the project team began substituting labour for the equipment. The supply of labour was abundant as nearby residents, up to one hundred at a time plus on-lookers, would come to the site looking for work. The project team discovered that most of the operations (opening a quarry, clearing the road, excavating and loading, spreading and shaping and compacting) could be accomplished by labour-intensive methods. The three operations that did need capital intensive methods were hauling and dumping (trucks), watering (waterbowsers) and finishing with final compaction. For some operations, such as excavating and loading as many as 150 labourers were employed. Although the quality of the road would be lower, a satisfactory result could be obtained by using heavy equipment (motorgraders, waterbowsers and rollers) to roll over the road one month after completion.

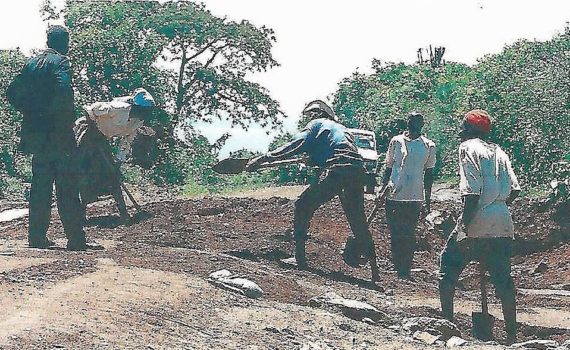

The photos shown here demonstrate how labour was employed to clear the road and spread gravel. The gravel was hauled from the gravel pits by trucks that had been loaded by hand.

Using a similar analysis as for the “ideal” capital-intensive methods, with the same assumptions, the project manager calculated that the direct operational cost of l kilometer of completed road was $550 using the “hypothetical most labour intensive” methods. It was possible to employ enough people on the different operations to obtain the same speed in gravelling 1 kilometre, ie 2.3 days.

Comparing the two methods: An “optimum balance”

The analysis revealed some striking numbers when the two methods were compared according to input factors and employment created and capital costs:

| Input factors

Per cent costs per km of road |

Capital intensive method | Labour intensive method |

| Equipment/fuel etc | 88 per cent | 44 per cent |

| Labour | 12 per cent | 56 per cent |

| Total work days created per km of road | 34 | 428 |

| Capital required tp create 1 work/day per km (US$) | 11.25 | 0.49 |

It was clear that some operations could adequately be accomplished through labour-intensive methods, while others absolutely required capital-intensive methods. Moreover, comparing the operational costs for certain operations (spreading, watering and compacting) between the two methods, the capital-intensive method was far more economical. The study suggested developing an “optimum balance” method, mixing the two technologies. One advantage of this new method would be to create employment, on the one hand, and eliminate the need for some costly heavy equipment such as a bulldozer and excavator, on the other hand. The author cautioned, however, that using this method would require careful planning, particularly network planning (critical path) in order to maximize the economic outputs and employment creation.

Labour-intensive methods: new management challenges

Several unforeseen problems were encountered when a large labour force was employed. As this method was totally unexpected, overall management and supervision was seriously unprepared for ensuring optimal work organization and productivity. Fortunately, responsibility and authority were delegated to gang leaders and headmen who became the keys to success. A puzzling question related to work organization was the absence of any standard on the amount of output that could be expected from one day of work. Even with the introduction of work study techniques it became difficult to motivate the workers to produce more, short of increasing pay or introducing bonuses. Yet this was not possible because of government wage regulations based on hours of work, not on output.

On the material side, housing and camp facilities presented few problems as most of the unskilled workers lived nearby in their own homes. The semi-skilled and skilled workers (about 30 in number) were housed in camps. The author sensed, however, that living accommodations would be a problem if camps had to be provided for a workforce of over 200 labourers. Food was readily transported from nearby towns. And although some camp dispensaries were established, medical supplies were short and remained a concern.

Finishing the project

Unsurprisingly, given the difficulties encountered, the project was critically behind schedule. After 10 months of operations, the project had only completed 50% of the work initially planned for 12 months. A foreign consultant engineering company was requested to help complete the work. The method was highly capital intensive accompanied by foreign staff: more and bigger machinery was used; except for truck drivers, all operators, supervisors and road foremen were European; and spare parts, fuel supplies were independently available. The road was made quickly and the quality was slightly better than the labour-intensive road.

As efficient as this completion was, the author noted several serious shortcomings: no employment was created – even food was imported-; there was virtually no on-the-job training for local peoples; all machinery was removed after the work; the local people did not feel that the road belonged to them, giving them little motivation to maintain and repair it; and the costs, although not known, were presumably financed with scarce foreign exchange.

{It is worth highlighting the significance of local participation and “ownership” in projects before turning to the conclusions. The author returned to the project site 25 years after his assignment. He discovered that the labour-intensive parts of the gravel road were better maintained than the other sections. The local villagers confirmed that they considered this “their” road.}

Conclusions and lessons learned

Rather than preferring one of the two methods, the author concluded that every project must be approached thoroughly to achieve an “optimum balance”. This would make it possible to determine the technology appropriate for different socio-economic conditions.

The issues recommended for review/guidance for the future were extensive. They focused on the availability of equipment and access to maintenance and repair; planned future use of the equipment; site location; availability of human resources according to skill levels; policies and plans for employment creation; possibilities for on-the-job training; material/logistic facilities; wage regulations; follow-up plans; and advantages and disadvantages of participation by local peoples.

Key lessons learned were highlighted for the future:

- Project design and planning from the outset were critical to success. Network diagramming and critical path methods were essential.

- Socio-economic conditions and human resource availability were as important as the technical and administrative considerations.

- Project management needed to adapt in order to cope with large numbers of workers as opposed to a few skilled machine operators. A broad project management training programme should include not only general and production management, but financial and human resource management as well as knowledge of employment creation potential of different technologies.

- Finally and perhaps most importantly the involvement of local people on a project creates a sense of “ownership” and is a motivating factor for maintenance and repair in the medium and long term, even without a formal programme.

Note:

Jens Müller in The International Labour Review (Vol. 101, no. 4, April 1970), “Labour-intensive methods in low-cost road construction: a case study”. The author was an official of the Management Development Branch, Human Resources Department at the time.

The Section of Former Officials of the ILO

The Section of Former Officials of the ILO